How our swimwear is so sustainable

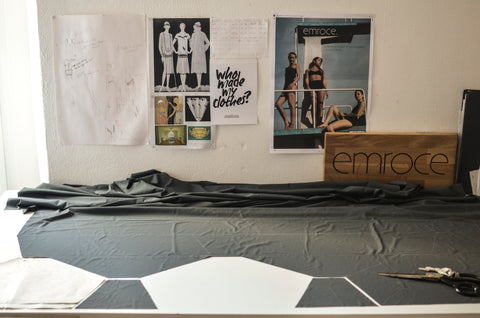

Swimwear design.

We aim to always make our swimwear zero waste and functional with a perfect fit.

We don't make anything for pure aesthetics. We don't follow trends. We cut every style back to it's basic necessities. We would never add an extra strap or frill to make the garment prettier. We would only do so, in order to make the garment function better or sometimes to fabric that would otherwise become waste.

Pattern making & cutting.

We use unbleached recycled paper to mark our patterns. We find working with paper patterns super therapeutic. This is the mindset within which, we find the fastest solutions tolaying out our zero waste patterns.

Each style is cut from a tessellating pattern which leaves no waste. We are left with a perfect line to work from after the cutting of each lay plan. In order to achieve zero waste 2 different styles or sizes are sometimes placed together in the same lay plan. Below you can see the cutting of the small High Wasters with the Mangia Fuoco top small

We cut everything by hand but when the business grows we would like to be using a large laser cutting machine in order to lower our labour costs and become more affordable for everyone.

Materials.

Renew prime made in Italy by Jersey Lomellina using Econyl regenerated nylon yarn made in Italy by Aquafil

Composition: 65% recycled nylon , 35% elastane

Please check this post for further information on this subject

Threads.

Fluffy nylon yarn - made in China by Meilun This a high stretch thread which must be used because otherwise the stitching will break when the garment is worn. After many months of searching, this was the first supplier who would offer us the low minimum order quantity we required.

100% polyester thread used for longevity. Natural threads breack down too quickly in the water unfortunately. We are transitioning to 100% recycled polyester thread which has recently become available.

Elastic tape.

HD tape - made in China by Yunze Garment Accessories

We use this as little as possible but it is a must for strengthening any seams which will be placed under a lot of preassure. Again, after searching for many months, this was the first supplier who would offer us the low minimum order quantity we required.

We choose to use HD tape which is a plastic tape, over rubber tape because we've found that it is the rubber decomposing within the swimwear which signals the end of the life of that swimwear when often the fabric is still good to wear.

Obviously we would like to use no plastic at all (recycled or not) but the technology of swimwear fabrics is still developing and only in the last few years sustainable swimwear fabrics have begun appearing on the market. Soon we will be experimenting with hemp fabrics to see if they can withstand our test of durability.

We need to make the garment last for as many years as possible in order to slow down fashion production and waste. The fluffy nylon yarn is an absolute must in swimwear production as is the elastic tape. The elastic tape could be made of natural rubber instead of plastic but in our past experiences this biodegraded faster than the swimsuit wore out. Besides ordering small quantities, We have yet to find sustainable alternatives for the nylon thread & elastic tape.

If you have any questions or information for us on this subject please contact us at emroce@gmail.com

All thread and elastic tape ends are recuperated and used as cushion filler.

Above image shows the amount of waste left from 2 years of work. These are small triangles mainly left over from trial and error. Instead of being thrown away they are used as frills in the childrens swimsuits.

Packaging & Shipping.

The swimwear is placed in a brown paper bag and closed with brown paper tape.

If your swimwear is arriving by post, the hangtag is attached with a compostable cotton thread.

If bought in store: Our hangtags are attached with a thin strip of our fabric which is sometimes left to the side of a zero waste lay plan due to slightly varying widths between colours.